BACKGROUND: A logging crew in the Southeast was clearcutting a tract and using a whole-tree chipper to process treelength pulpwood. After the crew had operated the machine for two weeks, the flail chains needed to be replaced; changing out the chains safely required three employees.

PERSONAL CHARACTERISTICS: The chipper operator and crew foreman were fully qualified to perform all aspects of their jobs. The foreman had 15 years of experience with a good safety record and was considered competent.

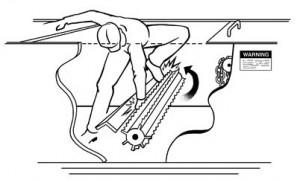

UNSAFE ACTS AND CONDITION: The operator had shut down the chipper and told the crew to wait until he drained the hydraulic pressure off the system. However, the foreman lifted the door to flail chain compartment, and once the door was opened he stepped on a stabilizer bar. The foreman was in a hurry and was trying to perform a job that needed two additional people. The machine was turned off, but there was residual pressure left in the system since the lockout procedures had not been completed.

ACCIDENT: As he stepped on the bar, the foreman’s left foot slipped between the stabilizer bar and the infeed roller. The roller has very sharp teeth. There was a two-inch gap between the roller and bar. The foreman tried to stop his fall, but when he reached out with his left hand, his left arm also got caught between the bar and the infeed roller. The pressure was enough to allow the chain that rotates the in-feed rollers to move when the foreman stepped on the roller. The pressure caused the roller to turn, and it trapped and mangled part of the foreman’s left arm and foot.

INJURY: The foreman suffered an amputation of the left arm just below the elbow and an amputation of part of his left foot.

RECOMMENDATIONS FOR CORRECTION:

- Daily safety reminders and frequent safety meetings are important to maintain focus on using the buddy system, so no one begins work on the chipper by himself or before lockout is complete. The crew must not open any panels until the chipper operator gives an “all clear” signal that the lockout procedure is complete.

- The owner has now installed a shutoff switch on the flail access door to prevent access until all systems have reached a zero energy state.

- The owner requested a complete OSHA inspection to help avoid a similar incident.

Courtesy of the Forest Resources Association: https://www.forestresources.org/

Courtesy of the Forest Resources Association: https://www.forestresources.org/