BACKGROUND: On a snowy February morning in northern New England, a cable skidder was being used to pull an empty tri-axle log truck up an icy hill to the log landing.

PERSONAL CHARACTERISTICS: The skidder operator was 37 years old and had worked in the woods in a variety of capacities for many years. He had worked for his current employer for approximately three years. Although he had attended the state’s logger training program prior to this employment, he had not completed the certification process and had received no additional training from this employer. At the time of the accident it is believed that he was wearing a hard hat and steel-toed boots.

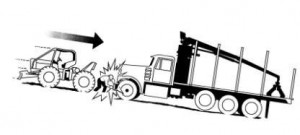

UNSAFE ACT OR CONDITION: After the log truck had been pulled up the hill, the two machines stopped 15 to 20 feet apart. The truck driver and the skidder operator both exited their machines and stood between the two machines to unhook the cable. It is unknown whether the emergency brake was set or if the blade of the skidder had been lowered to the ground.

ACCIDENT: As both men stood with their backs to the skidder, it began to roll, unnoticed, directly towards the truck. As the rear fender of the skidder impacted the front bumper of the log truck, the skidder operator was struck and crushed between them.

INJURY: The skidder operator suffered crushing injuries to his torso and lost consciousness immediately. Although CPR was begun promptly and emergency services arrived in approximately 10 minutes, the employee was pronounced dead by a doctor shortly thereafter.

RECOMMENDATIONS FOR CORRECTION: Through supervision and training, ensure that all machines are maintained in serviceable condition and that employees follow standard protocols for parking and towing. As OSHA requires, conduct a pre-shift inspection to ensure that braking systems (service and parking) are in serviceable condition, and that the machine is taken out of service until repaired.

For parking: ensure that parking brakes or transmission locks are set and that any implement (such as the skidder blade) is lowered to the ground prior to dismounting. On a hard surface, power the blade down until the blade becomes adequately weight-bearing—just dropping the blade with the force of gravity is inadequate to keep the machine from moving.

For towing:

• When possible, tow machine to a point of level ground.

• Separate towed machines by at least 30 feet.

• If there is a slope, park the uphill machine at an angle to the other machine (or, in this case, articulate the skidder), to that if it should roll, it would not be in a direct line to the towed vehicle.

• Set both machines’ parking brakes or transmission locks and lower implements with enough down-pressure to prevent rolling.

• Only one operator should dismount to unhook or retrieve cables or chains.

Courtesy of the Forest Resources Association: https://www.forestresources.org/page.asp?content=startpage&g=FRA