Battery Selection, Care

Batteries for forestry equipment have become increasingly expensive in recent years. With many skidders and other machines requiring more than one battery, it’s more important than ever for loggers to make sure they’re getting the most for their hard-earned money.

Battery Selection

Logging’s harsh operating conditions are especially tough on batteries. So when the time comes to replace a battery on one of your machines, be sure to choose one that not only meets your equipment manufacturer’s specifications for voltage and cranking power but is also engineered and built for heavy-duty commercial off-road applications.

High ambient temperatures are the leading cause of battery failure in forestry equipment. Ambient temperatures of 100º F are common for Southern loggers in sizzling summer weather, and batteries are often located in or near engine compartments. It is essential that the battery’s internal grids and lead/lead oxide plates be designed with the proper alloy materials to withstand these high temperatures.

Vibration, the second-leading cause of battery failure, is a special challenge in rugged forest conditions. Vibration can damage the materials coating the plates or grids, which can in turn cause short circuits and premature battery failure. For forestry applications, the plates must be anchored to the floor of the battery case. John Deere StrongBox® batteries, for example, use an “anchor bonding” technique in which the bottoms of the plates are set in epoxy to protect against vibration. To ensure you’re protected against vibration risks, don’t hesitate to ask your battery supplier whether a battery is built for heavy-duty commercial off-road use or employs plate anchoring.

Preventive Maintenance

Even the toughest batteries require regular preventive maintenance. If the battery is not sealed, it is designed to vent the sulfuric gas that is generated in the charge/discharge process. This “gassing” also allows some water content in the battery’s electrolyte solution to evaporate, and the water must be replenished periodically. For this type of battery, remove the vent caps and inspect the electrolyte level at least every six months—or as often as every month when temperatures top 100º F. If the electrolyte level is below the tops of the plates, refill each cell with distilled water. (Note: Never add tap water or electrolyte to a battery.)

Sealed “maintenance-free” batteries also require preventive care. Keep the tops of all batteries, the terminal posts and the cables clean. Dirt and debris can attract moisture that can lead to shorting between posts. Inspect for corrosion (from gassing) on posts and cables. Corrosion reduces battery efficiency and can lead to shorting and failure. Inspect each battery’s hold-downs, too, and tighten if necessary to minimize damaging vibration.

Even the best-cared-for battery eventually wears out, but it just makes good business sense to select a battery that’s designed and built for your equipment and application—and use common-sense preventive maintenance to ensure you’re getting the most productivity for your money.

Article by Alan Svoboda, Product Manager, John Deere Batteries

Latest News

Helene Hammered Private Timberlands

Based on preliminary damage assessments conducted by the Georgia Dept. of Agriculture, the Georgia Forestry Commission, and the University of Georgia, Hurricane Helene left behind an estimated $6.46 billion in damage to Georgia’s agriculture and...

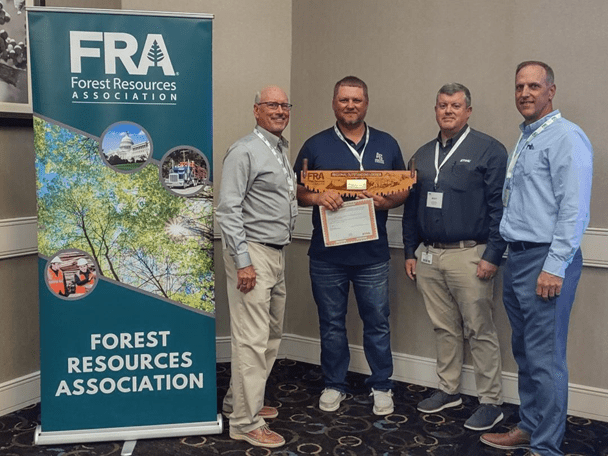

Aaron Street Recognized As FRA’s Appalachian Region Outstanding Logger

The Forest Resources Assn. (FRA) has honored Aaron Street of Aaron Street Logging from Sinks Grove, WV, as the 2024 Appalachian Region Outstanding Logger Award winner at FRA’s 2024 Joint Appalachian & Southeastern Region/Forest Products...

Have A Question?

Send Us A Message