Cutting Torch/Welding Safety: What's Wrong With This Picture?

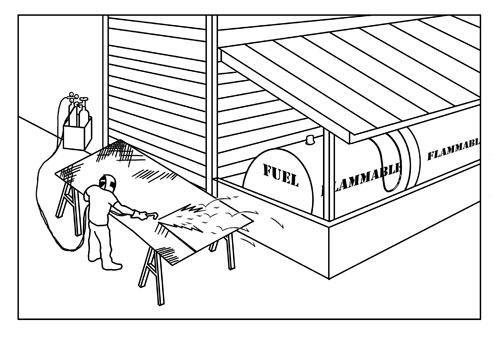

BACKGROUND: On a sunny summer day in the Northeast, a forester noticed an employee of a contractor cutting a piece of steel pate for repairs to equipment at the contractors’ garage. The accompanying illustration is based on a photo taken by the forester. What’s wrong with this picture?

BACKGROUND: On a sunny summer day in the Northeast, a forester noticed an employee of a contractor cutting a piece of steel pate for repairs to equipment at the contractors’ garage. The accompanying illustration is based on a photo taken by the forester. What’s wrong with this picture?

PERSONAL CHARACTERISTICS: The background, training and qualifications of the worker are unknown.

ACCIDENT/INJURY: Fortunately, there was no accident or injury resulting from this operation.

UNSAFE ACT OR CONDITION AND RECOMMENDATIONS FOR CORRECTION: FRA’S Garage Site Safety Manual (Publication 04-A-3) calls for the following procedures when performing oxy/acetylene welding and cutting. There appear to be several unsafe conditions in this image. See if you can identify them.

A. Gas cylinders are to be secured in an upright position.

B. Never use a regulator that appears to be damaged.

C. All exposed skin should be protected from sparks by using leather clothing provided by the company. The company uniforms are not flame retardant and not designed to be used in areas of flammability risk.

D. A dark face shield or goggles must always be worn during oxy/acetylene operations.

E. Always stand to the side of the regulators when opening the cylinder valves.

F. Cylinder valves should be opened slowly to prevent a rapid buildup of pressure in the regulators.

G. Proper pressure settings must be used for the tip and equipment in use to prevent dangerous backfires and flashbacks.

H. Be sure that reverse flow preventers and flash arresters are installed.

I. Check for leaks around regulators and hoses before lighting the torch. Leaks should only be checked with soapy water.

J. Keep hoses clear of falling sparks that could burn through while cutting.

K. Never allow oil to come in contact with hoses or equipment and never handle the equipment with hands or gloves that have grease on them.

L. Whenever possible, all combustible materials within a minimum of 35 feet must be removed.

M. Combustibles that cannot be removed as prescribed must be protected with a flameproof covering, and a fire watch must be posted during the welding or cutting procedure.

N. An approved fire extinguisher must be located within easy reach of the work site in case of fire.

UNSAFE CONDITIONS IN THE PICTURE:

• Item C: The worker was wearing leather gloves, but only a tee shirt, leaving his arms exposed

• Items L and M: Cutting too close to combustible fuel storage is the obvious issue in this case. Though sometimes it is difficult to avoid cutting or welding near combustibles, it was clearly avoidable in this case, if the worker had chosen a different location away from the fuel storage tank.

• Item N: No fire extinguisher was visible within easy reach. There may have been one inside the garage, too far away for quick use.

Courtesy of the Forest Resources Association: forestresources.org

Latest News

USA BioEnergy Closes On Land In Texas To Build $2.8 Billion SAF Refinery

USA BioEnergy (USABE) has closed on the acquisition of over 1,600 acres of land in east Texas for its new $2.8 billion advanced biorefinery, designed to convert wood waste into sustainable aviation fuel (SAF). The SAF facility has already secured a...

BioCharger, CharBoss From AirBurners Available For Demos

Air Burners is the world’s leading manufacturer of Air Curtain Burner Systems, offering the most economical and environmentally friendly solution for vegetative waste disposal. With decades of expertise, Air Burners has developed rugged, reliable...

Have A Question?

Send Us A Message