Log Smashes Into Truck's Unprotected Back Window

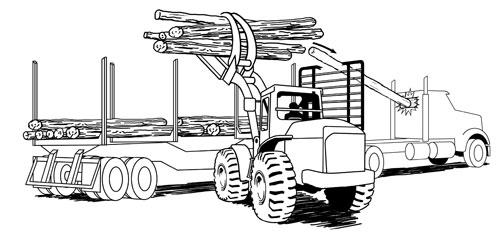

BACKGROUND: On a hot, dry, dusty late spring day in the Appalachians, a tractor-trailer full of sawlogs was being unloaded at the local log yard. The yard was flat and concreted.

BACKGROUND: On a hot, dry, dusty late spring day in the Appalachians, a tractor-trailer full of sawlogs was being unloaded at the local log yard. The yard was flat and concreted.

PERSONAL CHARACTERISTICS: The 47-year-old tractor-trailer operator had driven trucks for 23 years in the forest industry. He was considered fully trained, was known for paying attention to details, and had no previous injuries while driving.

UNSAFE ACT & CONDITION: In the past, the driver always made sure he was out of the tractor while the front-end loader unloaded the sawlogs from the trailer. Because of the windy, dusty conditions this day, the truck driver decided to stay in the cab of the truck and eat a portion of his lunch during the unloading process. The top, middle bar of the headache rack on his log trailer was missing.

ACCIDENT: When the log yard employee on the front-end loader raised one bunk of logs to clear the seven-foot log trailer bolsters, a tulip poplar log shot out of its bark and went through the void spot in the trailer headache rack. The log smashed into the back window of the tractor and pushed against the driver’s seat, forcing the seat and the driver forward. The driver of the truck was pinned against the steering wheel.

INJURY: The truck driver initially found it hard to speak. He was removed from the tractor and driven to the hospital. After some tests and observations were performed, he was released to go back to work.

RECOMMENDATIONS FOR CORRECTION:

- Never unload a trailer while the driver is still in the tractor. Woodyards should adopt and enforce safe unloading policies that address driver protection, visibility to or communication with the unloading machine operator, required Personal Protective Equipment, and other procedures.

- Tulip poplar sawlogs have a tendency to slip out of their bark in late spring to early summer. The loader operator should have started unloading with more pressure on the clam (grapple) while unloading this bunk of logs.

- If the operator notices some shifting of logs, he/she should immediately lower the bunk of logs back into the bolsters and then re-grip.

- Loader operators should never swing the loader grapple over the truck cab.

- All headache racks must be kept in serviceable condition.

Courtesy of the Forest Resources Association: forestresources.org

Latest News

Texas Fires Repsond To Active Forest Management

Although it may seem counterintuitive to fight fire with fire in the forest, a recent report by Mandy Chumley with the National Forests and Grasslands in Texas and Danielle Knight, Forest Service (FS) Southern Region and published in the Texas...

New OSB Project In Alabama Gains Permitting

Peak Renewables U.S. Inc. has received required permitting for the construction and operation of a greenfield 650MMSF oriented strandboard plant in Enterprise (Coffee County), Ala. Last February, the Enterprise City Council approved ordinances to...

Have A Question?

Send Us A Message