BACKGROUND: In late October in the Northeast, a mechanic for a logging and trucking contractor was working on an excavator at the contractor’s shop. The excavator was fitted with a brush grapple, which was used to feed logging slash into a chipper or grinder. The task at hand was to remove the hydraulic cylinder which controlled the excavator’s stick boom. The work was being completed on a paved surface in front of the full-service maintenance facility. The weather was mild and not a factor in this incident.

PERSONAL CHARACTERISTICS: The mechanic was 46 years old and had worked with this contractor for 8 years. He routinely worked on this and similar heavy equipment and was considered fully trained for this repair. He was wearing Personal Protective Equipment, including eye protection and steel-toed work boots.

UNSAFE ACT OR CONDITION: After the machine and boom had been placed in the proper service position, the hydraulic system pressure needed to be brought to zero. This was done by shutting the machine off, turning the key back to the run (but not start) position and cycling the hydraulic controls. It was thought that turning the key to recharge the electric system would allow the electric-over-hydraulic controls to dissipate any pressure still stored in the hydraulic system. Unfortunately this procedure did not eliminate pressure in the cylinder lines.

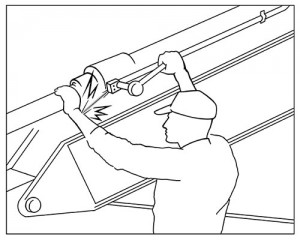

ACCIDENT: When the mechanic began to disassemble the hydraulic lines (in this case, a four-bolt flange with rubber O-ring); a high pressure oil jet shot from the fitting and struck the mechanic in the wrist. The high pressure oil punctured his skin and injected hydraulic oil into the tissue at the puncture site.

INJURY: Where the oil impacted the skin it left a bruise the size of a quarter and pierced a hole through the skin similar to a needle puncture. The mechanic immediately went to the office (in the garage) and reported the injury to the shop foreman. The foreman took the mechanic to the local walk-in care facility within 30 minutes. After initial evaluation at this facility, the doctor recommended the mechanic be immediately taken to a specialist. The mechanic was taken directly to a hand surgeon in the same town who successfully treated the entry wound and contamination by the toxic fluid.

The injury occurred mid-day on a Wednesday. The mechanic lost two and a half days of work, returning to work the following Monday, and was expected to be on light duty for a week or two. As the injury was treated promptly by a knowledgeable facility, the toxic effect of the hydraulic oil was expected to be minimal, and a full recovery was expected.

RECOMMENDATIONS FOR CORRECTION: At the time of the repair, the mechanic had not consulted the specific manual for this machine to determine the proper procedure to dissipate oil pressure throughout the system. During the accident investigation, the manual still could not be located. As increased technology has complicated shut-down procedures (the addition of hydraulic accumulators for example), no assumptions can be made, and a generic shut-down procedure should not be trusted. Machine-specific owners’ manuals should be readily available and consulted prior to undertaking repairs.

When searching for hydraulic leaks and servicing charged systems, heavy gloves will provide additional protection for the hands.

Courtesy of the Forest Resources Association: https://www.forestresources.org/page.asp?content=startpage&g=FRA