Near-Fatal Electrocution Involving Knuckleboom Loader

BACKGROUND: On a foggy and slightly rainy day in the Appalachians, a logging crew was moving a skidder and log loader to a new tract. The loader had been moved from the log deck to a location nearer the highway. The operators had chained down the bucksaw and delimber heel to the trailer, and the loader operator was in the process of “heeling” or securing the grapple to the boom. He did this by raising the boom straight up and causing the grapple to sway back to grab the heel on the boom. The skidder was still hooked to the loader during this moving process.

BACKGROUND: On a foggy and slightly rainy day in the Appalachians, a logging crew was moving a skidder and log loader to a new tract. The loader had been moved from the log deck to a location nearer the highway. The operators had chained down the bucksaw and delimber heel to the trailer, and the loader operator was in the process of “heeling” or securing the grapple to the boom. He did this by raising the boom straight up and causing the grapple to sway back to grab the heel on the boom. The skidder was still hooked to the loader during this moving process.

PERSONAL CHARACTERISTICS: The owner-operator and the loader and skidder operators were all experienced, with individual logging work histories ranging from 15 to 40 years. Two of them were “cardholders” with their state’s logger training & education program.

UNSAFE ACTS AND CONDITIONS: The loader was close to a low-strung power line that paralleled the state road. The loader operator saw that the owner-operator had secured the slasher saw and moved away from the loader. Without communicating with the loader operator, however, the owner-operator walked back over to the loader, grabbed some excess chain hanging from the trailer tongue and was touching the loader during the time that the operator had raised the boom quickly in order to “heel” the grapple.

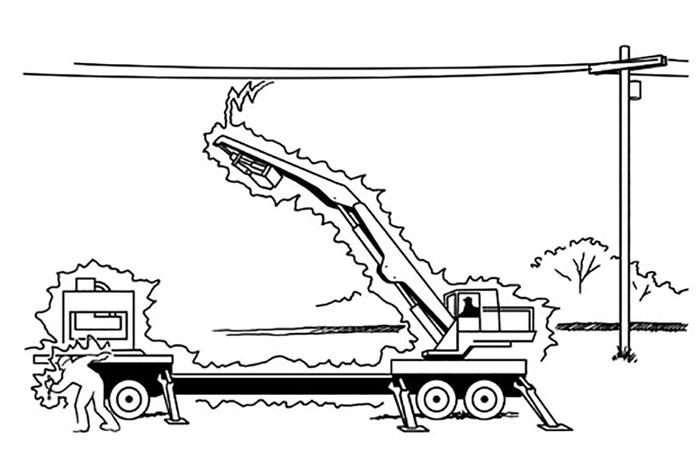

ACCIDENT: Although the loader boom was still several (10+) feet away from the power line, the electricity from the line arced to the loader boom. The skidder operator saw a green flash and then saw the truck driver nearby waving his arms. The loader operator also saw the truck driver waving and thought that the loader may have been too close to the power line, so he quickly lowered the boom. At this point the logging crew members saw the owner-operator lying on the ground.

INJURY: The equipment operators immediately looked for anything that might still be “live” with electricity and saw nothing. The operators exited their equipment and then checked the logger for a pulse and signs of life—there was no pulse or breathing. They immediately began CPR and called 911. The truck driver ran to the main road to flag down the ambulance, and First Responders were on the scene in minutes, followed by EMS. The paramedics took over CPR and “shocked” the logger’s heart back into rhythm. He was then transported to a local hospital. The logger sustained some mild burns on his right hand, and doctors had to remove a portion of a toe on his right foot. He survived the incident because of the immediate life-saving actions taken by the crew and the speedy arrival of paramedics and First Responders.

RECOMMENDATIONS FOR CORRECTION:

- Equipment operators must be aware of all hazards at the work site. Safety meetings should be conducted on the dangers of overhead hazards.

- Never operate a loader within 100 feet of any electric power line.

- During the equipment loading or moving preparation process, only the workers directly involved in running the equipment (or spotting/aligning the machine if loading onto a lowboy) should be in the immediate proximity. Individuals should not approach working, moving equipment.

- It is essential that crew members communicate visually and/or verbally when there is a worker on the ground. Additionally, high-visibility clothing or vests will improve safety to ground workers.

- Be aware that it is possible for electricity to arc to a machine even if it does not actually touch the power line. High humidity can increase the likelihood of electricity jumping from a power line to the equipment.

- Employers should ensure that each employee’s first-aid and CPR training remain up-to-date. Due to the rural nature of logging sites, ensure that emergency plans are in place for each site (911 or other emergency number, location/directions, who flags ambulance, etc.)

Courtesy of the Forest Resources Association: forestresources.org

Latest News

Highland Pellets Expanding To Mississippi

In late October Highland Grenada, LLC, an affiliate of Highland Pellets, LLC, announced the pending purchase of the former Georgeia-Pacific OSB mill site to build a new export pellet plant. According to news reports, the new plant will be a “replica” of…

Texas Seeks Higher BMP Compliance

In a recent report in the Texas Logger newsletter from the Texas Logging Council, the state Texas Forest Service (TFS) noted rates of state timber harvesting Best Management Practices (BMPs) compliance, officials with the Texas Forest Service say…

IP Closure Announcement Continues Market Shift

The pulp and paper industry continues its painful supply side market shift as officials with International Paper in late October announced the company will permanently close its containerboard mill in Orange, Tex., and will permanently cease…

Have A Question?

Send Us A Message