Skidder Strikes Crew Member’s Head, Runs Over Foot

BACKGROUND:

BACKGROUND:

On an early winter morning in the Southeast, a skidder driver was returning to his skidder after the crew’s morning safety meeting.

PERSONAL CHARACTERISTICS:

The 47-year-old skidder driver had only been employed for one week but had years of experience from other logging jobs. He was not wearing his hard hat and his high-visibility vest, as he had left them in the skidder.

UNSAFE ACTS AND CONDITIONS:

The operator of a second skidder was unaware of the other skidder driver still on foot when he left the safety meeting site. The skidder driver on the ground was not wearing all of the required Personal Protective Equipment and may not have been visible to the other skidder driver. (The line-of-sight on a skidder makes it difficult to see anyone close to the machine.) The second skidder operator started his machine and began moving it forward.

ACCIDENT:

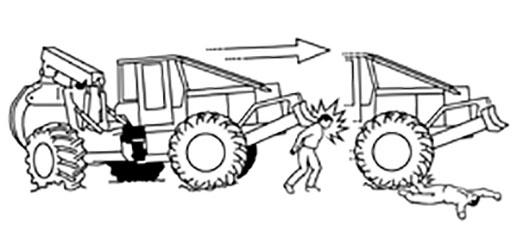

The on-the-ground skidder driver was hit in the head from behind by the skidder blade and knocked to the ground, landing on his back. He then tried to move out of the path of the skidder to avoid getting run over; however, the skidder tire ran over his right foot. The victim was able to get up and limp 200 feet towards the loader, where he attracted the attention of the owner.

INJURY:

The skidder operator suffered a head contusion and a fractured right foot.

RECOMMENDATIONS FOR CORRECTION:

- Employers must ensure that workers understand the hazards of ground personnel around moving equipment.

- Employers must ensure all ground personnel wear all required Personal Protective Equipment.

- Ground employees must be vigilant when walking near moving equipment.

- Employers should implement and enforce a written safety program which includes, but is not limited to, task-specific safety procedures and worker training in hazard identification, avoidance, and control.

- Employers must develop a communication system for employees to make operators aware when someone is near their equipment.

- Operators should keep equipment windows clean, and employers should replace windows that are significantly marred and have excess glare.

Courtesy of the Forest Resources Association: forestresources.org

Latest News

USA BioEnergy Closes On Land In Texas To Build $2.8 Billion SAF Refinery

USA BioEnergy (USABE) has closed on the acquisition of over 1,600 acres of land in east Texas for its new $2.8 billion advanced biorefinery, designed to convert wood waste into sustainable aviation fuel (SAF). The SAF facility has already secured a...

BioCharger, CharBoss From AirBurners Available For Demos

Air Burners is the world’s leading manufacturer of Air Curtain Burner Systems, offering the most economical and environmentally friendly solution for vegetative waste disposal. With decades of expertise, Air Burners has developed rugged, reliable...

Have A Question?

Send Us A Message